Measurement Systems Analysis: Features, Tools & Evaluation

Table of Contents

Introduction

Measurement data are the used more often and in more ways than ever before. For instance, the decision to adjust a manufacturing process is the now commonly based on measurement data. The data, or some statistic calculated from them, are the compared with statistical control limits for the process, and if the comparison indicates that the process is out of statistical control, then an adjustment of the some kind is made. Otherwise, the process is allowed to be run without adjustment. Another use of measurement data is to determine if you significant relationship exists between two or the more variables. For example, it may be suspected that a critical dimension on a moulded plastic part is a related to the temperature of the feed material. That is the possible relationship could be studied by using a statistical procedure called regression analysis to compare measurements of the critical dimension with measurements of the temperature of the feed material.

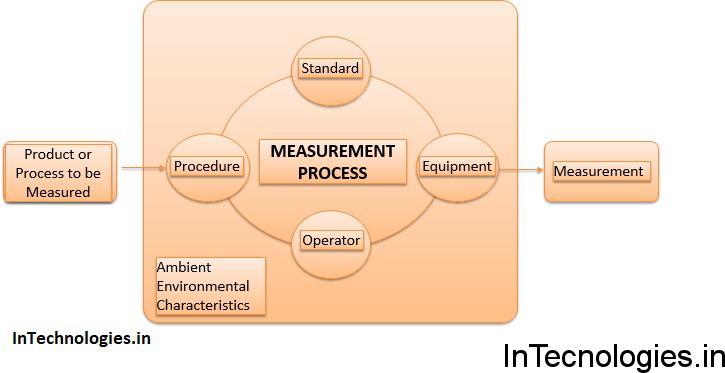

Measurement as a Process

Quality of Measurement Data

The (QMD) quality of measurement data the defined by statistical properties of the multiple measurements obtained for the measurement system operating under stable conditions. For the instance suppose that is the measurement of the system, operating under stable conditions, is the used to be obtain several measurements of the certain characteristic. If the measurements the all close to the master value for the characteristic, then a quality of the data is said to be high Similarly if some or all of the measurements are the “far away” from the master value, then the quality of the data is said to be “low”. The statistical system properties most commonly used to be the characterize quality of data are the bias and variance of the measurement system. The property called bias refers to the location of the data relative to a reference master value and the property called variance refers to the spread of the data.

Measurement System Features:-

Bias-Bias is the difference between the true value (reference value) and the observed average of measurements on the same characteristic on the same part. Bias is the measure of the systematic error of the measurement system

Linearity-Linearity is the difference in bias values at different points over the expected operating range of the measurement gauge. This tells you how accurate tour measurements are through the expected range of measurements.

Stability-Stability (or drift) is the total variation in the measurements obtained with a measurement system on the same master or parts when measuring a single characteristic over an extended time period. That is, stability is the change in bias over time

Repeatability-Repeatability is the variation in measurements obtained with one measurement instrument when used several times by one appraiser while measuring the identical characteristic on the same part. This is the inherent variation or capability of the equipment itself. Repeatability is commonly referred to as equipment variation (EV).

Reproducibility-Reproducibility is typically defined as the variation in the average of the measurements made by different appraisers using the same measuring instrument when measuring the identical characteristic on the same part. This is often true for manual instruments influenced by the skill of the operator.

Standards and Traceability

The National Institute of Standards and the Technology (NIST) is the principal National Measurements Institute (NMI) in the United States serving under the U.S. Department of the Commerce. National Institute of Standards and the Technology (NIST), formerly the National Bureau of the Standards (NBS), serves as the highest level authority for a metrology in the U.S. (NIST) primary responsibility is to be the provide measurement services and the maintain measurement standards that is assist U.S. industry in the making traceable measurements which ultimately assist in the trade of products and the services. NIST provides these services directly too many types of the industries, but primarily to those industries that is require the highest level of the accuracy for their products and that incorporate state-of-the-art measurements in their processes.

National Measurement Institutes

Most of the industrialized countries throughout the world maintain their own National Measurement Institutes (NMI) and the similar to NIST, they also provide a high level of the metrology standards or measurement services for their respective countries. NIST works collaboratively with these other NMIs to assure measurements made in one country do not differ from those made in the. This is accomplished through Mutual Recognition Arrangements (MRAs) and by the performing interlaboratory comparisons between the NMIs. One thing to be note is that the capabilities of these NMIs will vary from the country to country and do not all types of the measurements are compared on a regular basis, so differences can exist. This is why it is the important to understand to the whom measurements are traceable and the how traceable they are.

Traceability

Traceability is the important concept in the trade of goods and the services. Measurements that are traceable to the same or similar standards will be agree more closely than those that is are not the traceable. This helps reduce the need for re-test, rejection of the good product, and acceptance of the bad product.

Calibration Systems

A calibration system (CS) is a set of the operations that is establish, under specified conditions, the relationship between a measuring device and the traceable standard of the known reference value and the uncertainty. Calibration may also include steps to the detect, correlate, report, or eliminate by adjustment any discrepancy in accuracy of the measuring device being compared.

The calibration system (SC) determines measurement traceability to the measurement systems through the use of the calibration methods and the standards. Traceability is the chain of the calibration events originating with the calibration standards of the appropriate metrological capability or a measurement the uncertainty. Each calibration event includes all of the elements necessary including standards, measurement and the test equipment being verified, calibration methods and the procedures, records, and the qualified personnel.

Measurement Systems Evaluation Tools–

- Histograms

- Probability paper

- Run Charts

- Scatter diagrams

- Multi-Vari Charts

- Gantt “R&R” analysis

- Analysis of Variance (ANOVA)

- Shewhart “Control” Charts

True Value

The measurement process TARGET is the True Value (TV) of the part. It is T the desired that any other individual reading to be as close to this value as economically possible. Unfortunately, the true value can be the never known with the certainty. However, uncertainty can the minimized by the using a reference value the based on a well-defined operational definition of a characteristic, and the using results of the measurement system that has higher order discrimination and the traceable to National Institute of Standards and the Technology (NIST). Because the reference value is the used as a surrogate for the true value, these terms are commonly used interchangeably. This usage is not the recommended.

Statistical Properties of Measurement Systems

The ideal measurement system would produce only the correct measurements each time it is used. Each measurement would always agree with the standard. Measurement system that is could produce measurements like that is would be said to have the statistical properties of the zero variance zero bias and the zero probability of the misclassifying any product it is the measured. Unfortunately measurement the systems with such desirable statistical properties seldom exist and the so process managers are the typically forced to use the measurement systems that have less the desirable statistical properties (SPMS). The quality of measurement the system is usually determined solely by the statistical properties of data produces over time. Other properties such as the cost ease of use etc. Are also important in that they contribute to the overall desirability of the measurement system. But it is the statistical properties of the data produced that is determine quality of the measurement system. But it is the statistical properties of the data produced that is determine quality of the measurement system.

Sources of Variation

Similar to all processes, the measurement system is the impacted by both random and the systematic sources of variation. These sources of the variation are due to common and the special causes. In order to control the measurement system the variation:

1) Identify the potential sources of the variation.

2) Eliminate whenever possible or monitor these sources of the variation.

Although the specific causes will be depend on the situation some typical sources of the variation can be identified. There are various methods of presenting and the categorizing these sources of variation such as cause-effect diagrams fault tree diagrams, etc., but the guidelines presented here will focus on the major elements of a measuring the system.

The Effects of Measurement System Variability

The measurement system can be the affected by various sources of variation repeated readings on the same part do not yield the same identical result. Readings vary from each other due to common and the special causes.

The effects of various sources of variation on the measurement system should be the evaluated over a short and the long period of the time. The measurement system capability is the measurement system random error over a short period of time. It is the combination of errors quantified by the linearity uniformity repeatability and the reproducibility. The measurement system performance as with process performance is the effect of all sources of the variation over time. This is accomplished by the determining whether our process is in statistical control (i.e., stable and consistent; variation is due only to common causes) on target no bias and has acceptable the variation gage repeatability and reproducibility (GRR)) over the range of expected results. This is ads stability and the consistency to the measurement system capability.

Effect on Decisions

After measuring a part one of the actions that can be taken is to be determine the status of that part. Historically it would be determined if the part were acceptable within specification or the unacceptable outside specification. Another common scenario is the classification of parts into the specific categories.

Effect on Product Decisions

In the order to better understand the effect of measurement the system error on product decisions consider the case where all of the variability in multiple readings of a single part is the due to gage repeatability and the reproducibility. That is the measurement process is in the statistical control and has zero bias.

New Process Acceptance

The new process such as machining manufacturing stamping material handling heat treating or assembly is the purchased there often is a series of steps that are the completed as part of the buy-off activity. Oftentimes this is involves some studies done on the equipment at the supplier’s location and then at the customer’s location. If the measurement the system used at either location is not consistent with the measurement system that will be used under the normal circumstances then confusion may ensue. The most common situation involving the use of different instruments is the case where the instrument used at the supplier has higher order discrimination than the production instrument gage. For example, parts measured with a coordinate the measuring machine during buyoff and then with a height gage during production; samples measured (weighed) on an electronic scale or laboratory mechanical scale during buyoff and then on a simple mechanical scale during the production.

Process Setup/ Control (Funnel Experiment)

The manufacturing operations use a single part at the beginning of the day to verify that the process is the targeted. If the part measured is the target the process is then adjusted. Later in some cases another part is the measured and again the process may be adjusted. Dr. Deming referred to this type of measurement and the decision-making.

Consider the situation where the weight of a precious metal coating on a part is the being controlled to a target of 5.00 grams. Suppose that the results from the scale used to determine the weight vary 0.20 grams but this is not known since the measurement system analysis was never done. The operating instructions require the operator to verify the weight at setup and the every hour based on one sample. If the results are beyond the interval 4.90 to 5.10 grams then the operator is to setup the process again.

Measurement Strategy and Planning

The Planning is key before designing and the purchase of measurement equipment or systems. Many decisions made during the planning stage could affect the direction and the selection of measurement equipment. What is the purpose and how will the measurement result be the used? The planning stage will set the course and have a significant effect on how well the measurement process operates and the can you reduce possible problems and measurement error in the future.

Complexity

The type complexity and the purpose of measurement system may the drive various levels of the program management strategic the planning measurement systems analysis or other the special consideration for the measurement selection assessment and the control. Simple measuring tools and the devices i.e. scales measuring tapes and the fixed-limit or attribute gages may not require the level of the management planning, or analysis that more complex or critical measuring systems the demand i.e. master or reference CMM test stand the automated online gaging etc. Any measurement system may require more or less strategic planning and the scrutiny depending on a given product or the process situation. The decision as to the appropriate level shall be the left to the (APQP) team assigned to the measurement process and the customer. The actual degree of the involvement or implementation in many of the activities below should be driven by the particular the measurement system, consideration of the supporting gage control and the calibration system profound process knowledge and the common sense.

{ “@context”: “https://schema.org”, “@type”: “BlogPosting”, “mainEntityOfPage”: { “@type”: “WebPage”, “@id”: “https://intechnologies.in/measurement-systems-analysis/” }, “headline”: “Measurement Systems Analysis: Features, Tools & Evaluation”, “image”: “https://intechnologies.in/wp-content/uploads/2022/06/MSA-Process-InTechnologies.in_.jpg?v=1656262453”, “author”: { “@type”: “Person”, “name”: “In Technologies”, “url”: “https://intechnologies.in/” }, “publisher”: { “@type”: “Organization”, “name”: “In Technologies”, “logo”: { “@type”: “ImageObject”, “url”: “https://i0.wp.com/intechnologies.in/wp-content/uploads/2020/06/cropped-InTechnologiesNew.png?fit=182%2C121&ssl=1” } }, “datePublished”: “2022-05-30”, “dateModified”: “2022-05-30” }

0 Comments