Understanding Laser Beam Machine: Working, Types, Principles, Applications

Table of Contents

Introduction

Emergence of advanced engineering materials, stringent design requirements, intricate shape and unusual size of workpiece restrict the use of conventional machining methods. Hence, it was realized to develop some non- conventional machining methods known as advanced machining processes (AMPs). Nowadays many AMPs are being used in the industry such as; electro discharge machining, beam machining processes Laser beam machining (LBM), electron beam machining, ion beam machining and plasma beam machining), electrochemical machining, chemical machining processes chemical blanking, photochemical machining, ultrasonic machining (USM), and jet machining processes (abrasive jet machining, water jet machining, abrasive water jet machining), but these processes have their own limitations regarding workpiece material, shapes, etc. LBM is one of the AMPs which is used for shaping almost whole range of business materials.

Types of Laser

1. Gas laser

Gas lasers generally have a wide variety of characteristics. Gas lasers using many gases have been built and used for many purposes. They are one of the oldest types of lasers. For example, helium-neon (HeNe) lasers are common in education because of their low cost. Carbon dioxide lasers are often used in the industry for cutting and welding. Metal ion lasers are the gas lasers that generate deep ultraviolet wavelengths. Other examples are argon-ion, helium-silver (HeAg), neon-copper (NeCu), lasers, etc.

2. Solid laser

A solid-state laser is one in which the atoms that emit light are fixed within a crystal or a glassy material. For example, (a) Ruby rod the chromium atoms embedded in the ruby’s aluminium oxide crystal). (b) Yttrium orthovanadate (ND: YVO4), Yttrium lithium fluoride (ND: YLF) and Yttrium aluminium garnet transverse over the work piece and table can be moved as per requirement.

Principle of LBM

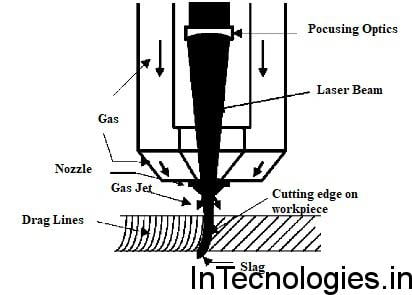

The material removal mechanism during laser beam machining (LBM) includes several stages, including melting, vaporization, and chemical degradation, in which chemical bonds are broken and materials degrade. When a high energy density laser beam is focused on the work surface, thermal energy is absorbed, which heats and transforms the work volume into a molten, vaporized, or chemically changed state that can be easily removed by the flow of the high pressure assist gas jet, which accelerates the transformed material and ejects it from the machining zone. The schematic of laser beam machining (LBM) has been shown in Fig. 1. Laser beam machining (LBM) is the thermal process.

Controlling Parameters

- For machining, the workpiece should be placed close to the lens. If the focal length is less, straight holes will be produced. If the focal length is greater, taper holes will be produced.

- Power density: the power density of the beam determines whether the beam will perform the function of cutting or welding. For machining operations, the power density should be higher, i.e., around 1.5107 W/cm2.

- Focal length: it is the distance between the laser beam and the workpiece. If the laser is very close to the workpiece, the divergence of the beam occurs for a small focal length in the metal cutting.

- The properties of machined materials or magnetic materials are not affected by laser beam machining.

- Cutting through air, gas, vacuum, and even liquid is possible with laser beam machining (LBM).

- In this process, no burrs or chips are produced.

- Angular drilling or cutting can be obtained by tilting the piece.

- Mechanical force is not exerted on the workpiece, resulting in smooth machining of the fragile work.

Advantages of Laser Beam Machining

- There’s no direct contact between the tool and the workpiece, as no physical tool is required.

- The absence of a tool provides no solution to tool wear issues.

- Microholes with a large depth-to-diameter ratio can be drilled by using laser beam machining (LBM).

- The properties of machined materials or magnetic materials are not affected by laser beam machining.

- Cutting through air, gas, vacuum, and even liquid is possible with laser beam machining (LBM).

- In this process, no burrs or chips are produced.

- Angular drilling or cutting can be obtained by tilting the workpiece.

- When a mechanical force is not exerted on the workpiece, it results in smooth machining of the fragile piece.

- Any metal or non-metal can be machined, like tungsten, ceramics, zincromium, etc.

Applications of LBM

- Laser welding it is useful for the joining sheet metal or stock pieces of the about 2.5 mm thick or less. Many metals and the alloys can be welded by laser like low carbon steel, stainless steel, titanium and it’s the alloys, silicon bronze, etc. another advantage of laser welding is no need of the grinding after welding.

- Laser cutting: a laser beam can be used in the cutting metals, plastics, ceramics, textiles, cloth and even glass. It can also use for the cutting complex shapes with sharp concern and the slots. It is useful for the cutting of steel, titanium, nickel, certain refractory materials and the plastics but cutting of aluminium and copper has been the especially problematic.

- Laser drilling it has ability to the make small and very small holes of the shallow depth. Most of the laser beam machining are useful for drilling of small holes in the fuel filters, carburettor nozzles, hypodermic needles, jet engine blades cooling holes, etc. in the aircraft turbine industry, laser drilling used for making holes for the air bleeds etc.

Disadvantages of Laser Beam Machining

- The capital and operating cost is the very high.

- The material removing rate is the very low.

- It cannot cut reflective and the highly conductive material like aluminium, copper and it’s the alloys.

- Skilled operator is the required for channelling and the operating process.

- The output energy of the laser is difficult to the control precisely.

- Safety procedures are to be followed strictly for safe and the trouble-free performance.

- Machined holes may have taper from entry to the exit.

- Flash lamp has the limited life.

Design guidelines

- LASER works best on materials such as carbon steel or the stainless steels.

- Metals such as aluminium & the copper alloys are more difficult to cut due to their ability to reflect the light as well as absorb & the conduct heat.

- This requires lasers that are more powerful.

- LBM is not the bulk material removal process.

- It is the most suited to contour cutting, slitting & the drilling small diameter deep holes.

- Length to diameter ratios of up to the 50:1 are possible.

- There are special methods to the create blind or stepped features, but they are the less accurate.

- Sharp corners are the possible, but radii should be provided for in the design.

- Some distortion may be caused in the very thin parts.

- Maximum workpiece the thickness:

○ mild steel: 25mm,

○ stainless steel: 13mm,

○ aluminium: 10mm. - Localized thermal stresses & the heat affected zones result.

Pumping process

- Generally, the number of atoms or molecule generally, the number of atoms or molecule raised to a higher energy level N2 population of raised to a higher energy level N2 population of the higher energy level atoms is less than the the higher energy level atoms) is less than the population N1 of lower energy level. Population N1 of lower energy level.

- For laser action, the population of atoms in the for laser action, the population of atoms in the higher energy state should be increased. The higher energy state should be increased. The process of increasing the population of higher process of increasing the population of higher energy level i.e. making Energy level i.e. making N2 >> N1 is called asN1 is called as population inversion population inversion.

- The method of achieving population inversion is the method of achieving population inversion is called pumping pumping.

Equipment

- Three important elements of any laser Three important elements of any laser device are:

- Laser medium collection of atoms, Laser medium collection of atoms, molecules, or ions molecules, or ions.

- Pumping energy source – required to Pumping energy source – required to excite these atoms to higher energy level excite these atoms to higher energy level

- Optical feedback system Optical feedback system.

Conditions required to produce a laser

- Many, if not all, materials can be made to undergo Many, if not all, materials can be made to undergo stimulated emission given the right circumstances stimulated emission given the right circumstances

- However, to build a working laser two conditions need to be However, to build a working laser two conditions need to be met:

1. Energy source that provides the initial stimulation must be Energy source that provides the initial stimulation must be powerful enough to ensure that the majority of the atoms powerful enough to ensure that the majority of the atoms or molecules in the material to be lazed are at their higher or molecules in the material to be lazed are at their higher energy level energy level.

Laser Cutting Parameters

The process of laser cutting involved many parameters, which can be the generally divided into two main categories—beam parameters and the process parameters.

1. Beam Parameters

These are parameters that characterize properties of the laser beam which include the wavelength, power, intensity and the spot size, continue wave and the pulsed power, beam polarization, types of the beam, characteristics of beam the beam mode.

A.Wavelength

The wavelength depends on the transitions in the process of stimulated emission with respect to the physical mechanisms involved in the energy coupling and the process efficiency, stability and the quality wavelength plays a most decisive role. It has important effect on the material‘s surface absorptivity.

2. Process Parameters

These are parameters that characterize of the laser beam which include focusing of laser beams, focal position and the dual focus lens, process gas and the pressure, nozzle diameter, stand-off distance and alignment, and the cutting speed.

A.Focusing of Laser Beams

The focal length of a lens is the distance from the position of the focal lens to the focal spot. In the fibre laser system, the laser beam is delivered by the fibre optics, which use a collimator to form the divergent laser beam. After that, it comes to the focusing lens or mirror, and it focuses a parallel laser beam on to the work piece. The cutting process necessitates a small enough spot size to produce high intensity power. The focal length of the lens has a large impact on the size of the focal spot and the intensity of the beam in the spot.

B.Focal Position

In order to get the optimum cutting result, focal point position must be controlled. There are two reasons for this: the first is that the small spot size produced by the focusing laser beam results in a short depth of focus, requiring the focal point to be positioned rather precisely with respect to the surface of the work piece; the second is that variations in material and thickness may necessitate alterations to the position of the focus point.

Abstract

The quality of the laser cut is the most important factor in the laser cutting process. All cutting parameters may have a significant impact on the final work quality. In general, cutting parameters are adjusted and tuned to provide the quality of cut desired. However, this takes a significant amount of time and effort. Therefore, it is important to investigate the impact of cutting parameters on the quality of the cut. The aim of this study is to relate the CO2 laser cutting parameters, namely laser power, cutting speed, and laser scanning speed.

Conclusion

Laser beam machining is one of the most widely used unconventional machining methods that is capable of producing complex and precise shapes with very little tolerance. The main focus is on the laser drilling, laser cutting, and laser-induced bending. The execution of this Laser Beam Machining (LBM) required professional expertise, and the operational costs are quite expensive. There have been many advancements in Laser Beam Machining (LBM) over time, and it is the assisted processes as well as optimization techniques that have led to some new research areas in Laser Beam Machining (LBM). Modeling technique advancements have opened up new research avenues in Laser Beam Machining (LBM), as well as improved the process’s performance.

0 Comments