Plasma Arc Welding: Principles, Types, Features, and Benefits

Table of Contents

Introduction

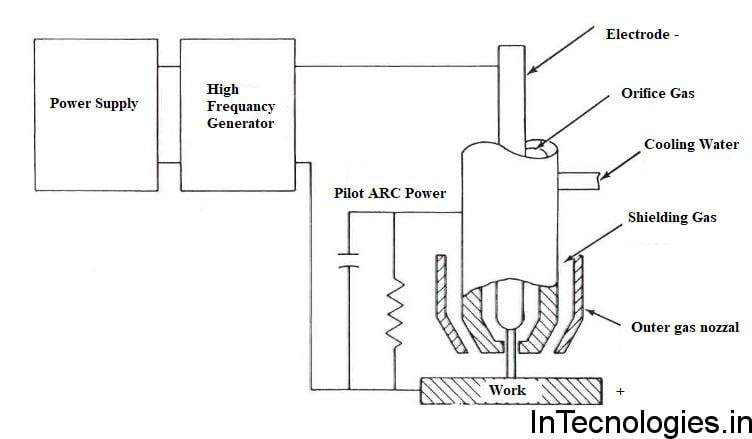

Plasma Arc Welding, an extension of Gas Tungsten Arc Welding (GTAW), has the advantages of fewer welding defects and excellent direction control and has been used in space shuttles, airplanes, rockets, and other applications. In PAW, the electric arc generated between a non-consumable tungsten electrode and the working piece is constrained using a copper nozzle with a small opening at the tip. A full setup of plasma arc welding is shown in figure 1.

As shown in fig 2, an arc is formed between the electrode and workpiece transfer plasma arc welding (PAW) and the water-cool nozzle non-transfer PAW. By forcing the plasma gas and the arc through a constricted orifice, the torch delivers a high concentration of energy to a small area, giving higher welding speeds and producing welds with high penetration width ratios, thus limiting the HAZ dimensions. For this reason, plasma arc welding (PAW) is a very useful technique for welding austenitic steels, structural steels, etc.

Plasma Arc Welding

Plasma is the state of matter when part of the gas is ionized, making it a conductor of the electric current. It is the state of the matter present between the electrodes in any arc. Plasma is the fourth state of matter, following solid, liquid, and gas.This is an extremely hot substance that consists of free electrons, positive ions, atoms, and molecules. It is what conducts electricity.

PLASMA ARC WELDING (PAW) can be defined as a gas-shielded arc welding process where the coalescence of metals is achieved via the heat transferred by an arc that is created between a tungsten electrode and the workpiece. The arc is constricted by a copper alloy nozzle orifice to form the highly collimated arc column. The plasma is formed through the ionization of a portion of the plasma orifice gas. The process can be operated with or without a filler wire for the addition.

Principles of Operation

Once the equipment is set up and the welding sequence is initiated, the plasma and shielding gases are switched on. When the torch is brought into close proximity to the workpiece or when the selected welding current is initiated, an arc is transferred from the electrode to the workpiece through the orifice in the copper alloy nozzle, at which point a weld pool is formed. The PAW process can be used in two distinct operating modes, often described as the melt-in mode and the keyhole mode.

The melt-in-mode refers to a weld pool similar to that which typically forms in the gas-tungsten arc welding (GTAW) process, where a bowl-shaped portion of the workpiece material that is under the arc is melted. In keyhole mode, the arc fully penetrates the workpiece material, forming a nominally concentric hole, or keyhole, through the thickness. The molten welding metal flows around the arc and solidifies behind the keyhole as the torch traverses the workpiece.

Advantages and Disadvantages

The advantages of the PAW process are:-

- Greater thicknesses of metal can be penetrated in a single pass, compared with other processes, such as GTAW.

- This greater amount of penetration allows a reduced amount of joint preparation.

- The process can produce high weld integrity (similar to GTAW) so minimizing weld passes and, hence, welding times and labor costs.

- The longer arc length allows better viewing of the weld pool, which is important in manual welding.

Typical Welds/Joint Configuration

- Spot fusion welds

- Corner/edge fusion welds

- Flange fusion weld

- Square butt fusion welds

- Surface fusion welds

- Lap fusion welds

1. SPOT WELDING

Plasma arc welding is well suited for spot fusion welding because of its reliable arc-starting characteristics and high response time. It is commonly used for tacking, joining, and sealing operations. All metals that can be welded with a gas tungsten arc can be spot welded with a plasma arc. process.

2. FUSION WELDING

Plasma arc welding can be used in all positions when using the melt-in mode. Typically, the circumferential and longitudinal seam welds are welded in the flat positions. The corner edge and the surface fusion lamination welds provide improved travel speeds and reduce heat input in the vertical down position. Typical procedures and the operating parameters

3. JOINT DESIGN AND FIXTURING

In many cases, the common practises in joint design and features typically used with gas tungsten welding can also be incorporated with plasma arc welding. The use of copper or aluminium heat sinks in many applications can enhance the welding operation. When thin metals are welded, both joint edges must be in continuous contact and must melt simultaneously to fuse together into a single weld puddle. Separation between the joint edges before or during welding will allow the edges to melt separately and remain separate.

Much larger tolerances for joint flanging can be obtained by flanging the edges. Turned-up edges act as the pre-placed filler wire to fill the gap and ensure melt contact between the sides of the joint. They also stiffen joint edges to minimise warpage from heat built up during the welding. Flanging is recommended for all butt joints in foil thicknesses below 0.010″ (0.25 mm).

4.FILLER METAL ADDITION

Filler wire can be added to the leading edge of a plasma weld puddle, as in the gas tungsten arc process. Wire-height adjustments are not generally as critical with plasma arc welding because wire can lift off the plate and melt into the plasma stream without contaminating the electrode. However, wire placement is still important because the wire can ball up when lifted from the plate.

Principle Of Plasma Arc Welding

- Plasma arc welding is the process where coalescence is produced by heat that is developed from the special setup between a tungsten alloy electrode and the water-cooled nozzle for non-transferred arc welding or between a tungsten alloy electrode and the job-transferred arc welding.

- This process employs two different gases for the two different purposes

1) one gas is used to form the Arc plasma.

2) Second gas is used to shield the arc plasma.

Keywords of Plasma Arc Welding

- Plasma: A gas heated to a very high temperature and ionized so that it becomes conductive.

- Pilot arc: First arc between electrode & the constricting nozzle.

- Keyhole: A welding technique in which the concentrated heat source penetrates the WP forming a hole at the leading edge of the molten weld metal.

- Sinter: Integrate into a solid or porous mass by means of heating.

Working Of Plasma Arc Welding

- The plasma arc welding process is normally compared to the gas tungsten arc process.

- The plasma torch contains an electrode made of tungsten fixed in a nozzle made of copper. The arc is started between the electrode and the nozzle tip. The material to be welded is then exposed to an arc or flame.

- The small opening forces gas to travel through a constricted opening, or orifice. This concentrates heat on the smaller area. This ability allows the welder to produce a very high-quality weld.

- The result is a process that gives higher welding speeds, less distortion, more consistent welds, less spatter, and more control over the weld area.

Equipment For Plasma Arc Welding

- Power source: open circuit voltage of the 80 volts

- Current: The 50 – 350A

- A DC welding current is the required

- High frequency the generator

- A cooling system: The water recirculation

- Plasma the welding torch

- Plasma the gas

- Shielding gas: Argon, Argon Hydrogen, or the Helium

Types of Plasma Arc Welding

1. Transferred Arc Mode

- Arc is the strike between the electrode (-) and the workpiece (+)

- Generally used for the high-speed welding

- Work is part of the electrical circuit

- Heat is the obtained from anode spot and from the plasma jet

- Greater energy transfer to the work

- Higher penetration is the obtained, so thicker sheets can be the welded

- Used to the weld ceramics, steels & the aluminium, copper, titanium, nickel alloys

2. Non – Transferred Arc Mode

- Arc is the struck between electrode (-) and the nozzle (+)

- Work is the not part of the electrical circuit

- Heat is the obtained from plasma jet only

- Less energy is transfer to the work

- Less penetration is obtained so thin sheets can be the welded

- Used for the cutting and joining non-conductive work the piece

Applications Of Plasma Arc Welding

- Aerospace Industries

- Cryogenics

- Foodstuff and Chemical Industries

- Machine and Plant Construction

- Automobiles and Railways

- Ship Construction

- Tank Equipment and Pipeline Construction etc.

Operating Modes

- Three operating modes can be produced by varying bore diameter and plasma gas flow rate:

- Micro plasma 0.1 to 15A.

- Medium current: 15 to 200A.

- Keyhole plasma over 100A.

What we can do with plasma arc cutting

- Accurate cuts can be made in stainless steel and non-ferrous metals such as aluminum by plasma arc cutting.

- The cuts are made by the high-temperature, high-velocity gas jet generated by the constricting arc between a tungsten electrode and the component.

- The heat from the arc melts metal, and the gas jet removes molten metal from the cut.

- The arc runs in an inert inner shield, while the outer shield protects the cut surface.

- Argon, helium, nitrogen, and mixtures of these gases are used for both the inner and outer shields.

- Plasma arc cutting is characterized by fast cutting speeds and is mainly used in mechanized systems.

- The cutting is accompanied by a high noise level, which can be reduced by operating the torch underwater.

Features & Benefits of Plasma Arc Welding

One of the most important features of the plasma arc welding process is the protected electrode, which provides higher efficiency and reduces downtime in most applications. The tungsten electrode, which is secured inside the plasma torch, as well as the orifice behind it, are shielded from outside impurities that would normally attack the hot surface. With this protection, the electrode is shielded from materials that can constantly attack an exposed electrode. The protected electrode in the plasma welding torch normally requires a change only once every 8 hours for the majority of operations. This reduction in the electrode change allows for increased productivity.

Advantages Of Plasma Arc Welding

- Increase the welding speed.

- High energy is available for the welding. It can be easily used to weld hard and thick work pieces.

- The distance between the tool and the work piece does not affect the arc formation.

- low power consumption for the same size weld.

- A more stable arc is produced by the PLASMA ARC WELDING (PAW) method.

- The high penetration rate or the high intensity arc.

- It can work at low amperage.

Automatic/Manual Operation, Pilot Arc

Compatible with all Thermal Arc plasma welding torches, the WC 100B features a reliable arc starting by means of the pilot arc. It offers advantages in low-current welding operations and in repetitive, high-duty-cycle, automatic applications. The pilot arc can be used in either interrupted or continuous mode. At low currents or in high-duty-cycle, fast-cycling welding, the latter provides greater arc stability as well as instant arc starting.

Other features include an LED amperage voltage display; a large, easy-to-read plasma; and the shield gas flow meters’ internal torch lead connections for increased safety. Plug in the enclosed relays and the auxiliary control receptacle for automatic or manual operation of the Hi-Low pilot current switch to provide the best arc starting characteristics at the various main arc current levels.

Future Prospects and Conclusions

Continuous experimental studies are going on in the field of PLASMA ARC WELDING (PAW) in order to optimise the process and extend the range of materials it can weld. It was understood from the earlier works that most of the work in plasma arc welding was carried out to improve weld bead quality by changing process parameters such as the welding current, welding speed, torch stand distances, etc. Examine the wire form of filler metal used in welding and the powder form of filler metal used in coating from the literature. Powder plasma arc welding, a new technology with both mechanical and metallurgical properties, is being developed to improve weld quality by using powder as a filler metal in the welding process.

0 Comments