Understand Lean Manufacturing: Benefits, Tools, Principles & Techniques

Table of Contents

Introduction

The international labor Organization (ILO) is the tripartite United Nations (UN) the agency. Since 1919 the international labor Organization (ILO) brings together governments employers and the workers representatives of 187 member States to set the labor standards develop policies and the devise programmers promoting decent work for all women and the men. Based on the above mentioned mission the idea of developing this manual came as a contribution from the international labor Organization (ILO) Cairo Office to highlight the importance of adapting the Lean Manufacturing principles in the production process especially in Food Textile and the Ready-made Garments industries. Lean manufacturing is the management philosophy that focuses on continuously eliminating any possible waste in the production process. This manual sheds the light on points that increase the company capabilities to control a number of the resources labor overproduction space the defects unnecessary human motion inventory and the transportation.

Mass Production and Push System

Pioneered by the Henry Ford mass production adds the following to industrial revolution era’s the principles:

- Standard products and the operational efficiency

- Flow Usage of the conveyors at final assembly

- Economies of the Scale

- Special purpose machinery the product specific

- Go No Go the gauges

- More precise parts for the easy assembly.

The History of Lean

After World War the Japanese manufactures were faced with the dilemma of vast shortages of material financial and the human resources. The problems that Japanese manufacturers were faced with the differed from those of their Western the counterparts. These conditions resulted in the birth of lean manufacturing the concept. Toyota Motor Company led by it’s the president Toyoda recognized that American automakers of the era were out-producing their Japanese counterparts in the mid1940’s American companies were the outperforming their Japanese counterparts by a factor of the ten.

In order to the make a move toward improvement early Japanese leaders such as the Toyoda Kiichiro Shigeo Shingo and the Taichung One devised a new disciplined process the oriented system which is known today as the Toyota Production System or the Lean Manufacturing. Taichung One who was given the task of developing a system that would enhance productivity at the Toyota is generally considered to be the primary force behind this is the system.

One drew upon some ideas from the West and particularly from Henry Ford’s book today and the Tomorrow. Ford’s moving assembly line of the continuously flowing material formed basis for the Toyota Production System. After some experimentation the Toyota Production System was developed and the refined between 1945 and 1970 is the still growing today all over the world. The basic underlying idea of this system is to minimize the consumption of resources that add no value to the product.

What Is Lean

The new uprising in the manufacturing goods and service sector has created great challenges for the US industry. The customer driven and the highly competitive market has rendered the

old-fashioned managerial style an inadequate tool to the cope with these challenges. These factors present a big challenge to the companies to look for new tools to continue moving up the ladder in a global competitive growing the market. While some companies continue to the grow based on economic constancy other companies struggle because of their lack of understanding of the change of customer mind-sets and the cost practices.

To get out of this situation and to the become more profitable many manufacturers have started turn to the lean manufacturing principles to elevate the performance of their firms. The basic ideas behind the lean manufacturing system which have been practiced for the many years in Japan are waste elimination cost reduction and the employee empowerment. The Japanese philosophy of the doing business is totally different than the philosophy that has been long prevalent in the US. The traditional belief in the west had been that the only way to the make profit.

Lean Manufacturing Tools and Techniques

Once companies pinpoint the major sources of waste tools such as the continuous improvement just-in-time production production smoothing and the others will guide companies through corrective actions so as to the eliminate waste. In the following sections a brief description of such tools is the given.

1.Cellular Manufacturing

Cellular manufacturing is one of the cornerstones when one wants to the become lean. Cellular manufacturing is the concept that increases mix of products with the minimum waste possible. A cell consists of the equipment and workstations that are arranged in an order that maintains a smooth flow of the materials and components through the process. It also has assigned operators who are the qualified and trained to work at the cell.

2.Just-In-Time

Closely associated with the lean manufacturing is principle of the just-in-time since it is a management idea that attempts to the eliminate sources of manufacturing waste by producing the right part in right place at the right time. This addresses waste such as the work in process material defect and the poor scheduling of parts delivered the Naomi’s1997. Inventory and the material flow systems are typically classified as the either push traditional or pull just in the time systems. Customer demand is the driving force behind both the systems.

However the major difference is in the how each system handles customer the demand. Just in time is a tool that enables the internal process of a company to the adapt to sudden changes in the demand pattern by producing the right product at right time and in the right quantities Menden, 1998. Moreover just in time is a critical tool to manage the external activities of a company such as purchasing and the distribution. It can be thought of as consisting of the three elements JIT production JIT distribution and the JIT purchasing. More details are given for each in the following sections.

3.Continuous Improvement

Continuous improvement is the another fundamental principle of lean the manufacturing. Kaizen which is the Japanese word for a continuous endeavor for the perfection has become popular in the west as a paramount concept behind good the management. Kaizen is the systematic approach to gradual orderly continuous the improvement. In manufacturing settings improvements can be take place in the many forms such as reduction of the inventory and reduction of the defective parts.

One of the most effective tools of the continuous improvement is 5S which is the basis for an effective lean the company. 5S is the first modular step toward serious waste the reduction. 5S consists of the Japanese words Seri Sort Seaton Straighten Seiko Sweep and the Clean Seekers Systemize and the Shinseki Standardize. The underlying concept behind 5S is to the look for waste 12 and then to try to the eliminate it. Waste could be in the form of scrap defects excess raw material unneeded items the old broken tools and obsolete jigs and the fixtures Menden1998.

4.Production Smoothing

In a lean manufacturing system it is the important to move to a higher degree of process

control in order to strive to the reduce waste. Another tool to accomplish this is the production smoothing. Heijunka the Japanese word for the production smoothing is where the manufacturers try to keep the production level as constant as possible from day to the day Womack et al 1990.

Heijunka is a concept adapted from the Toyota production system where in order to the decrease production cost it was necessary to build no the more cars and parts than the number that could be the sold. To accomplish this the production schedule should be the smooth so as to effectively produce the right quantity of parts and efficiently utilize the manpower. If the production level is not constant this leads to the waste such as work-in-process inventory at the workplace.

5.Other Waste Reduction Techniques

Some of the other waste reductions tools include zero defects setup reduction and the line balancing. The goal of zero defects is to the ensure that products are fault free all the way through continuous improvement of the manufacturing process Karson et al 1996. Human beings almost invariably will be the make errors. When errors are made and are not the caught then defective parts will appear at end of the process. However if the errors can be prevented before they happen then defective parts can be the avoided.

One of the tools that zero defect principle uses is the poke yoke. Poke yoke which was developed by the Shingo is an autonomous defect control system that is the put on a machine that inspects all parts to the make sure that there are zero the defects. The goal of poke-yoke is to observe the defective parts at the source detect cause of the defect and to avoid moving the defective part to next workstation the Feld 2000.

6.Total Productive Maintenance

Machine breakdown is one of the most important issues that concerns people on the shop floor. The reliability of equipment on the shop floor is very important since if one machine breaks down the entire production line could go the down. An important tool that is necessary to the account for sudden machine breakdowns is total productive the maintenance. In almost any the lean environment setting a total productive maintenance program is the very import.

7.Standardization of Work

The very important principle of waste elimination is the standardization of worker the actions. Standardized the work basically ensures that each job is the organized and is carried out in the most effective manner. No matter who is the doing job same level of quality should be the achieved. 20 At the Toyota every worker follows the same processing steps all the time. This is a includes the time needed to finish a job order of the steps to follow for each job and parts on the hand.

By doing this one the ensures that line balancing is achieved unwarranted work in process inventory is the minimized and non-value added activities are the reduced. A tool that is used to the standardize work is what called the take time is. Take German for rhythm or the beat time refers to how often a part should be produced in the product family based on the actual customer the demand.

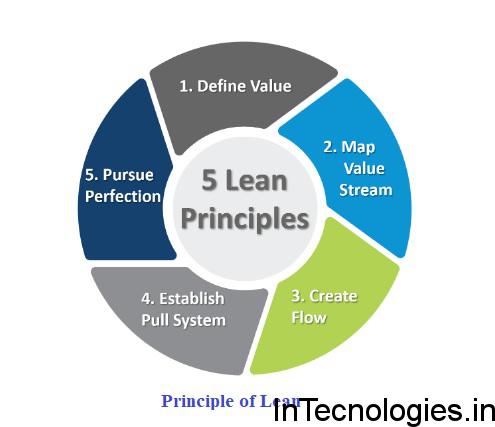

The 5 Key Lean Manufacturing Principles

1.Specify the Value of Your Work

What is the value of your work as perceived by your the customer? Identify the value that your customer is paying for or the value that your customer participates in you’re the business because of. This value may be your the unique varieties or products the practices you use to make them or the quality of your products or the services.

2.Map the Steps in Your Value Chain

Map out all the steps in your work as you create that value for you’re the customer. This may start at the taking inventory before ordering ingredients purchasing receiving mixing making a product packing taking orders delivering etc. Start by the writing or mapping out the process step by the step.

3.Establish Customer Pull

Find ways to the create customer pull for your products instead of having to the push sales based on your production the output. Drive demand instead of the needing to find homes for the product.

4.Make the Process Flow Smoothly

Look at all the steps in your work process and eliminate waste and the friction points. If there are steps that don’t create the value as perceived by you’re the customer take them out of the process for the product? See flip side for types of waste to the think about.

5.Pursue Perfection

Create a culture of the continuous improvement continue to eliminate wastes and the document and standardize the processes. Make quality and the improved processes an ongoing the commitment.

The 8 Types of Waste

1.Waiting

Are workers waiting on the direction between tasks is there a bottleneck in the your packing process is decision-making a holdup in you’re the operation.

2.Overproduction

Did you plant to the much Did you hire more people than you need for your sales the forecast Are you throwing out excess product after market or the wholesale orders Are you having lots of the meetings without action.

3.Over processing Or Incorrect Processing

Did products get the bunched when you need them loose Is someone trimming every root hair off the every beet Are you wasting time and effort by doing too the much.

4.Unnecessary Transport or Conveyance

Are you the moving things around that don’t create value for the customer How many times are you transporting the product before it gets to the customer.

5.Excess Inventory

Are you the carrying more supplies than you the need Did you put up more product than you you need.

6.Motion

Do you spend a lot of the time looking for things you need to complete the process are you making special trips for the frequently used tools Can you simplify your team’s physical movements to find the efficiency.

7.Unused Skills or People Potential

Are your people in the positions they’re trained for Are there ideas for improvement from the team Are there skills your team doesn’t have that could boost the value of your work.

8.Defects

Do you have to spend a lot of the time checking over other people’s work to make sure it meets you’re the quality needs Are you reworking or fixing problems with the orders.

0 Comments