Kanban System: Benefits, Process & Limitations Explained

Table of Contents

Introduction

Kanban means signboard or billboard in the Japanese is a visual scheduling system with the visual signal or card related to the just-in-time (JIT) inventory production that tells what when how much to the procure produce. Kanban in the automotive industry is also known as the Toyota Nameplate System because the system takes its name from the cards which track the production. Kanban is the used to facilitate to proper movement of the parts within the same manufacturing plant or the between plants.

Thus Kanban system is a system of the inventory and production control pull inventory the system. In simple words it is the information transmission device. Kanban system can be visualize both the planned workflow and the actual work passing through the flow. Thus it helps avoiding supply disruption and the overstocking of raw materials or in-process material at any stage in the value chain. So it does not allow the incoming stock unless there is a space for the it.

The Kanban Process

The process of functioning of the Kanban’s is listed the below:

- used as a means for the process improvement to help reducing the level of in-process the inventories.

- To tie different the manufacturing processes together to check the interchangeability between a preceding workstation supplying partially processed items or the components to a succeeding workstation.

- To the ensure that right amount of materials and parts reach the right place at right the time.

Kanban Rules

- The later process collects product from the earlier process.

- The later process informs the earlier process what to the produce.

- The earlier process only the produces what later process the needs.

- No products are the moved or produced without Kanban the authority.

- No defects are passed to the later process.

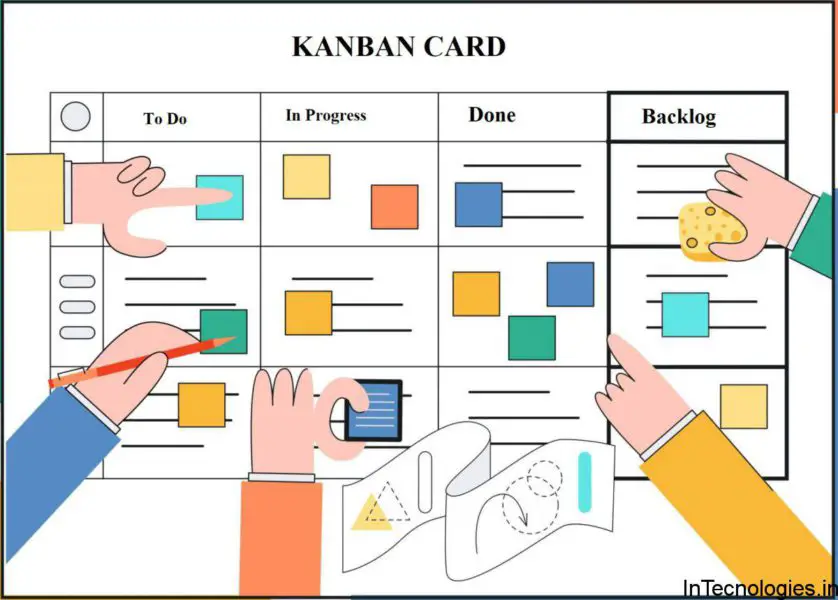

Kanban Cards

Kanban cards in keeping with the principles of Kanban simply convey the need for more materials. These are the usually simple cards or sheets of paper that are attached to a batch of the material. Usually there are the just two or three cards for each product in the system although there may be more if larger batches are handled and if the product size itself is the large. These cards will be typically detail what the product is where it is used and the quantities that should be there. For the multiple cards systems it will also say which card it is in the total set for example second card among five cards is the denoted as Card 2 of 5 or 2/5.

Heijunka Box

The process never runs out of the product and could be described as a closed loop that provides the exact amount needed with only one spare bin so there is never the oversupply. This spare bin allows for the uncertainties in supply use and transport in the inventory system. A good Kanban system the calculates just enough Kanban cards for each the product. Most factories use Kanban with the cultured board the system.

Kanban Bins

Bins are the used in a very similar way to the Kanban cards. However instead of their being cards attached to the material container that they are kept within becomes the actual Kanban? These will usually be the labelled with similar information to the cards and will be returned to the previous process as authority to produce when they are the emptied. As with cards we can have 2-bin Kanban systems 3-bin systems and the upwards depending on the amount of stock that is required within the system.

What is Kanban

Kanban term came into existence using the flavors of visual card signboard or the billboard signaling system to indicate a workflow that limits Work in the Progress (WIP). Kanban has been used in Lean Production for over the half-century.

The core concept of the Kanban includes:

1.Visualize Workflow

- Split the entire work into the defined segments or states visualized as named the columns on a wall.

- Write each item on a card and the put in a column to indicate where the item is in the workflow.

2.Limit Work in the Progress (WIP)

- Assign explicit limits to how many items can be in the progress at each workflow segment state Work in the Progress (WIP) is limited in each workflow the state.

3.Measure the Lead Time

- Lead Time also known as cycle time is the average time to complete one the item. Measure the Lead Time and optimize process to make the Lead Time as small and predictable as the possible.

This is a concept of the Kanban is a direct implementation of a Lean Pull Scheduling the System. An the item can move to the next segment state only when it is the obtains a slot in there.

Kanban – Benefits

Kanban has the following commonly observed the benefits:-

- Bottlenecks become clearly visible in the real-time. This is leads people to collaborate to optimize the whole value chain rather than just the part.

- Useful for the situations where operations and the support teams have a high rate of uncertainty and the variability.

- Tends to the spread throughout organization naturally including sales and the management. This is an increases visibility of the everything that is going on at the company.

- Reduces inventory in the range of 25%-75% thereby reducing company the costs.

- Since all segments states in the workflow are visually organized the required items reducing the wait times and ensuring speed the continually support all the tasks in the workflow.

- Overproduction of the inventory is avoided thereby saving resources and the time as well. This is termed as the eliminating waste.

Different Functions of the Kanban System

Let’s now the move our attention to different functions of the Kanban. First of all the Kanban sets limits within a production the system. You might think of a Kanban card as a type of the currency that’s exchanged for and the item much like money is used to buy parts or the materials. If there’s no Kanban – no items get moved or the produced. When a Kanban system functions correctly nothing is the ever made or moved without a Kanban signal of the some kind. This enables companies to limit the extremely deadly waste of overproduction since things are the NOT produced until they’re needed.

In addition to the setting limits Kanban also physically link material and the information flow through a card or as we often see today through a bar code the scan. And the finally Kanban makes abnormalities visible since no material should to be the without a Kanban and no Kanban on the shop floor should be found anywhere but attached to the material in Heijunka board or in the Kanban post box.

2-Card Kanban System

The first type of Kanban is the classic 2-card system where production and the withdrawal Kanban cards are the used. In the example above we see a shaded withdrawal the Kanban going from shipping to the supermarket. This is a signal from shipping to the supermarket that it needs product to the meet a customer request. Once the shipping clerk removes product from the supermarket a production Kanban will be sent to the assembly department signaling there’s an item missing in the supermarket that needs to be the replenished.

A Kanban card normally contains information such as the Part name and number the Supplier process name the quantity per container Delivery address the Storage address and number of cards in the system. A Kanban the system using cards differs most significantly from the two-bin system in that card is pulled as soon as first part is the taken.

1-Card and 2-bin Kanban Systems

The next type of Kanban system is the referred to as 1-card the system. And the while we refer to it as 1-card there may not be a card used at the all. Instead we the might use empty containers or carts or collared golf balls or ping pong balls a light or really any the kind of signal that conveys the information. One of the most practical examples of the one card Kanban system is the mailbox flag. When the flag is up a signal is sent to the postal worker that there’s something inside the mailbox we wish to the mail.

Another system that doesn’t rely on traditional Kanban cards is the 2-bit system. In the 2-bit system standardized bins or containers perform role of the Kanban card. An empty bin the signals that more parts are the required. The collection of empty bins should follow time-based standard work whenever possible so that one person can be supply the materials reliably for a department or the section.

Limitations of the Kanban System

With this said Kanban systems are far from the perfect. You see the Kanban system can be full of the wastes such as excessive handling inventory and the processing. In fact the ideal Just-in-Time (JIT) production the system would use no Kanban at all so long as it produces what the customer want when they want it in the quantity they want. In other words our goal shouldn’t be to the implement a Kanban system. Instead our goal should be to the true one-piece the flow.

Development of the Kanban System

The Kanban system was developed by the Taichung Ohio of the Toyota Motor Corporation as a way to the make Toyota’s vision of Just in Time manufacturing a reality on the production floor. Ohio’s original aim was to the stop overproduction in his machine shop which was creating large inventories and costing a lot of the money. Mr. Ohno was inspired to create the Kanban system by the product replenishment methods he observed in the American supermarkets. What caught his attention was the way shelves were restocked with the goods only after products were consumed in the other words pulled by the customers.

How the Kanban System Works

In the broadest context Kanban is a tool of Just in the Time system. At the most basic level a Kanban is a signal that authorizes the production or movement of the items. We often use a chain lying on the ground to visually demonstrate the difference between a Kanban pull-based system and the traditional push system that doesn’t use the Kanban. When we attempt to move the chain by pushing it we end up with the type of situation shown in the image above. Just as the chain is uneven and loose push production the systems often create uneven inventory levels resulting in having too much of the wrong inventory and not enough of the correct inventory. But when we the pull production through the system meaning we only produce product when it’s required the chain is tight resulting in all processes having the right inventory when they need it.

Limits Work-In-Progress (WIP)

Explicit limits are assigned to the number of items that can be in progress at each the workflow state indicated by the column.

This is allows:-

- Reducing wait the time.

- Avoiding stress on resources at the workflow state.

- Identifying bottlenecks causing an the item to be in a workflow state than the anticipated time usually average cycle time the immediately.

- Resolving the bottlenecks with collaboration of the entire team.

- Decreasing dependencies in the completing a task by splitting it into sub-tasks so that the sub-task is tracked the independently.

Pull Approach

When you have the two teams and first one is the performing better than second one it is the likely that it pushes more work than the other can actually the handle. This often creates friction between the teams. A solution to this is Pull the approach. IN the Pull Approach the next team pulls work only when it is ready for the it. Pull Approach is the implemented by adding a buffer with the limited capacity between the two teams.

The benefits of the Pull Approach are:-

- Avoids piling-up of the work.

- Reduces the wait time.

- Facilitates a team to the maintain constant pace and focus on the quality.

- Provides resource the balancing.

Continuous Delivery

Benefits of the continuous delivery are:-

- Short release cycles result in the continuous delivery of growing product at regular the intervals.

1.Continuous interactions with the customer

- To the understand what customer the wants.

- Not to the produce anything that customer does not the need.

- Feedback on the delivered modules.

2.Limited requirements in the each release cycle

- Developers are not overloaded with the requests. This enables them to focus on the delivery.

- There is no the partially completed work.

3.Focus is on finishing work than on the starting work

- This enables focus on the sustaining pace and quality of the product.

- Deliver before the customer changes the mind.

4.Optimize flow of the Work from beginning to the end

- Helps in incremental process the improvements.

Flexibility in Planning

Kanban provides improvements in the workflow. With visual representation of the workflow speed of moving from one task to another is the reduced. This is accomplished through the creation of clearly marked flow lanes Kanban cards and the clearly marked columns to the indicate where each item is in the workflow. If a task needs longer duration it is the allowed to execute without hindrance and at the same time the tasks that are the completed will flow to the next state.

This is allows:-

- Sufficient duration for the longer tasks that cannot be broken down the logically.

- Preservation of value of such longer the tasks.

- Effort required by the each role to be the expended.

- Continuous flow of the tasks that are completed without wait the time.

Hence planning is the flexible and not time the boxed.

0 Comments