Geothermal Energy Power Plant: Understanding Generation & Design

Table of Contents

Introduction

The Geothermal energy is enormous and last for several millions of years. Hence it is called renewable energy. There is the large amount of heat lying in earth’s interior in the form of Volcanoes, geysers and hot springs. This thermal energy contained in the interior of the earth is called geothermal energy. Magma is the molten rock within the earth is pushed up towards the surface where the heat of the magma is being conducted upward through an overlying rock layer.

The hot magma near surface solidifies into the rock. The heat of magma is the conducted upward to this igneous rock. Ground water which finds it’s the way down to this rock through cracks is heated by heat of the rock or by mixing with hot gases and steam from the magma. The heated water convectively rise upward and into the porous and permeable reservoir above the igneous rock.

History of Geothermal Energy

Many ancient peoples, including the Romans, Chinese, and the Native Americans, used hot mineral springs for the bathing, cooking, and the heating. Water from hot springs is the now used world-wide in spas, for the heating buildings, and for agricultural and the industrial uses. Many the people believe hot mineral springs have natural healing the powers. Using geothermal energy to the produce electricity is the relatively new industry. It was initiated by a group of the Italians who built an electric generator at Lardarello in the 1904.

Were in Their generator was powered by the natural steam erupting from the earth. The first attempt to develop geothermal power in the United States came in the 1922 at The Geysers steam field in the northern California. The project failed because pipes and turbines of the day could not stand up to the abrasion and corrosion of the particles and impurities that the steam. Later, a small but successful hydrothermal plant opened at the Geysers in the 1960.

Benefits of Geothermal Energy

Renewable: Through proper reservoir management, rate of the energy extraction can be balanced with the reservoir’s natural heat recharge rate.

Base load: Geothermal power plants produce electricity consistently, running 24 hours per day 7 days per week, regardless of the weather conditions.

Domestic: U.S. geothermal resources can be the harnessed for the power production without importing fuel. Small Footprint: Geothermal power plants are the compact; using less land per GWh (404 m2) than (3642 m2) wind (1335 m2) or solar PV with the canter station (3237 m2).

Clean: Modern closed-loop geothermal power plants emit on the greenhouse gasses; life cycle GHG emissions (50 g CO2 eq/kWh) are the times less than solar PV, and six to the 20 times lower than natural gas. Geothermal power plants consume less water on the average over lifetime energy output than the most conventional generation technologies.

Where Is Geothermal Energy Found

What does the geothermal energy look like? Some visible features of the geothermal energy are volcanoes, hot springs, geysers, and the fumaroles. But you cannot see most the geothermal energy. Usually geothermal energy is the deep underground. There may be no clues above ground to the exists below ground. The Geologists use many methods to the find geothermal resources. The may study aerial photographs and the geological maps. The may analyse chemistry of the local water sources and the concentration of metals in the soil. The may measure variations in gravity and the magnetic fields.

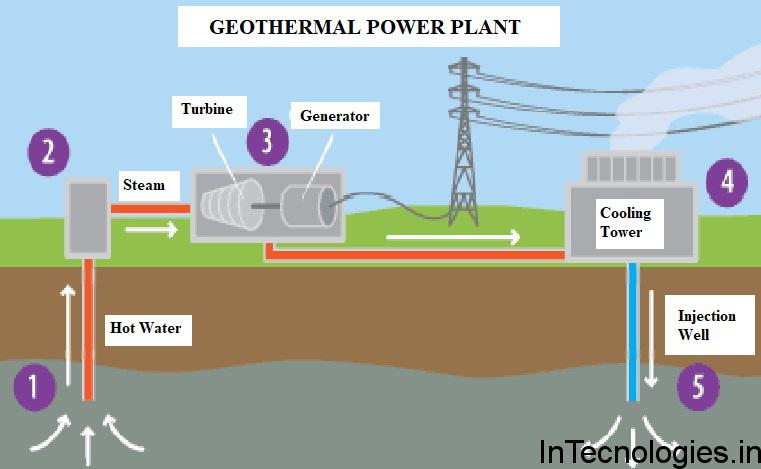

Geothermal Power Generation Plant

The heat content of a geothermal field will be the define power generation technology to be the used. Power generation from the geothermal resources requires resources with high to the medium heat content. Geothermal power generation currently is the based on following four technology options Long et al the 2003:

1.Direct dry steam plants

In this case, conversion device is the steam turbine designed to directly use the low-pressure, high volume fluid produced in the steam field. Dry steam plants commonly use the condensing turbines. The condensate is re-injected closed cycle or evaporated in the wet cooling towers IEA-ETSAP, 2010.

2.Flash plants

These are most common type of the geothermal electricity plants in the operation today. They are similar to the dry steam plants; however, steam is the obtained from a separation process called flashing. The steam is then directed to the turbines, and the resulting condensate is sent for re- injection or further flashing at the lower pressure IEA-ETSAP, 2010.

3.Binary plants

These plants are usually applied to the low or medium enthalpy geothermal fields where resource fluid is the used, via heat exchangers, to heat a process fluid in the closed loop IEA- ETSAP, 2010.

4.Combined-cycle or hybrid plants

Some geothermal plants use a combined cycle which adds a traditional Ranking cycle to produce electricity from what otherwise would become waste heat from a binary cycle (IEA-ETSAP, 2010). Using two cycles provides relatively high electric efficiency Dippy, 1999; Than, 2009.

Process and Technology Status

Geothermal energy is the heat derived within sub-surface of the earth. Water and the or steam carry geothermal energy to the earth’s surface. Depending on it’s the characteristics, geothermal energy can be used for the heating and cooling purposes or can be harnessed to the generate clean electricity. Geothermal power generation has higher capacity factors compared with the some other renewable energy resources and is the capable of supplying base load electricity, as well as providing ancillary services for the short- and long term flexibility in the some cases. Furthermore, geothermal power generation has lower life-cycle greenhouse gas emissions than the fossil fuel-based generation (IPCC, 2011). Geothermal energy can be sourced from the virtually everywhere.

Costs

Geothermal Power the Technology Brief12 Source IRENA, 2017b geothermal power projects are the capital- intensive; however, they have very low and the predictable operating costs. The total installed costs of a geothermal power plant cover exploration and the resource assessment, including: exploration drilling; drilling of the production and injection wells; field infrastructure, geothermal fluid collection and the disposal systems, and other surface installations; power plant and it’s the associated costs; project development costs; and the grid connection costs. Furthermore, cost ranges of the geothermal power plants will depend largely on the power plant type flash or binary well productivity number of well and the other geothermal field characteristics.

Overview of Power Plant Designs

This chapter addresses geothermal to the electrical power conversion systems typically in use in the world today. These may be divided into the three basic systems, wiz.

- Flashed steam/dry steam condensing system; resource temperature range from about 320°C to the some 230°C.

- Flashed steam back pressure system; resource temperature range from the about 320°C to some 200°C.

- Binary or twin-fluid system based upon Kalian or the Organic Rankings cycle; resource temperature range between 120°C to the about 190°C.

Power house equipment

1.Turbine

The problems potentially associated with the turbine are scaling of the flow control valve and nozzles primarily in the stator inlet stage ; stress corrosion of rotor blades; erosion of turbine rotor and stator blades and turbine housing. The rate and seriousness of scaling in the turbine are directly related to the steam cleanliness, i.e. the quantity and characteristics of separator “carry-over“. Thus the operation and efficiency of the separator are of great importance to trouble free turbine operation. Prolonged operation of the power plant off-design point also plays a significant role. Most of the scaling takes place in the flow control valve and the first stator nozzle row.

2.Generator

It must to be the pointed out here that high-temperature steam contains a significant amount of the carbon dioxide CO2 and some hydrogen sopite H2S and the atmosphere in geothermal areas is the thus permeated by these gases. All electrical equipment and the apparatus contains a lot of cuprous or silver components, which are highly susceptible to the sulphite corrosion and thus have to be kept in and the H2S free environment. This is the achieved by filtering the air entering ventilation system and the maintaining slight overpressure in the control room and electrical control centres.

3.Condenser

The steam-water mixture emitted from the turbine at outlet contains a significant amount of non condensable gases comprising mainly CO2 (which is usually 95–98% of the total gas content), CH4 and H2 S, and is thus highly acidic. Since most high-temperature geothermal resources are located in arid or semi-arid areas far removed from significant freshwater (rivers, lakes) sources, the condenser cooling choices are mostly limited to either atmospheric cooling towers or forced ventilation ones.

The application of evaporative cooling of the condensate results in the condensate containing dissolved oxygen in addition to the non-condensable gases, which make condenser fluid highly corrosive and the require condenser to be clad on the inside with stainless steel; condensate pumps to be made of the stainless steel, and all condensate pipelines either of the stainless steel or glass reinforced plastic.

Abstract

The paper gives an overview of the existing power plant technology. It addresses various problems that have been encountered, and the outlines countermeasures that have been applied. Two main types of the geothermal power plants are common, condensing power plant, using fluid from the reservoirs with temperatures in the range 200–320°C, and the binary fluid power plant using temperatures as low as the 120°C.

Also featured are the principal advantages appropriate to the utilisation of geothermal resources for production of the electricity. The paper moreover touches upon some of the advantages accruable from the integrated use of geothermal resources using same resource for the electricity production in cascade or parallel with production of hot water for the alternative uses, taking hybrid conversion as a case in the point.

Gas evacuation system

As the previously stated geothermal steam contains a significant quantity of the non-condensable gas (NCG) or some 0.5% to 10% by weight of steam in the very worst case. To the provide and maintain sufficient vacuum in the condenser, the non-condensable gas NCG plus any atmospheric air leakage into the condenser must be forcibly exhausted. The following methods are the typically adopted, viz:

- The use of a single or two stage steam ejectors, economical for the non-condensable gas (NCG) content less than 1.5% by weight of steam.

- The use of mechanical gas pumps, such as liquid ring vacuum pumps, which are economical for high concentration of the non-condensable gas (NCG).

- The use of hybrid systems incorporating methods 1 and 2 in the series. The advantages of ejector systems are the low maintenance, and high operational security of the systems. The disadvantage is significant pressure steam consumption, which the otherwise would be available for the power production.

Power Plant Design Parameters

The most important power plant design the parameters are.

1.Resource

- Steam conditions: Optimum turbine inlet steam pressure. Gas % NCG in the steam.

- Size thickness and areal extent, and the long term capacity, and natural recharge.

- Temperature and the pressure of deep resource fluid.

- Chemical composition liquid and gas phase of the deep fluid.

- Geology, stratigraphy, lithology and the geothermal reservoir properties faults, fractures, formation porosity, mineral alteration types and age, type of the permeability.

- Reservoir permeability.

- Thickness of the production/injection zones.

- Well productivity/infectivity.

- Two phase zones.

- Reservoir response to the production/injection.

- Natural state modelling, computer simulation of reservoir, and the model predictions.

- Reservoir monitoring and the management.

2.Accessibility

- Topography of the resource area.

- Remoteness from the population centres.

- Closeness to nature parks and the environmentally restricted areas.

3.Market

- Size, type and security of the market.

- Proximity of the market.

- Accessibility to the existing power transmission lines, substations.

4.Permits

- Resource concessions.

- Exploration permits.

- Drilling permits.

- Development permits.

- Environmental Impact Assessment.

- Building and the other permits.

Pre and post investment studies, business plan

All the above parameters are important to the development plan, production and the injection well drilling and we’ll be the design. They are no less important in the selection of power plant type, siting of the power station, production and injection well siting arrangement well be the spacing, etc., production and injection well numbers etc. It also plays a key-role in the planning development increment size and the timing.

0 Comments