Flexible Manufacturing Systems (FMS): Definition, Types, Objectives, Components Database

Table of Contents

Introduction

In the middle of the 1960s, market competition became more intense. From 1960 to 1970, the cost was the primary concern. Later, quality became the priority. As the market became more and more complex, speed of delivery became something customers also needed. A new strategy was formulated: customizability. The companies have to adapt to the environment in which they operate to be more flexible in their operations and to satisfy different market segments. Thus, the innovation of the flexible manufacturing system (FMS) became related to the effort to gain a competitive advantage.

First of all, the flexible manufacturing system (FMS) is the manufacturing technology. Secondly, flexible manufacturing systems (FMS) are the philosophy. The system is the keyword. Philosophically, the flexible manufacturing system (FMS) incorporates a system view of manufacturing. The buzzword for today’s manufacturer is agility. An agile manufacturer is the one who is the fastest to market, operates with the lowest total cost, and has the greatest ability to delight its customers. The flexible manufacturing system (FMS) is simply one way that manufacturers are able to achieve this agility.

The objectives of a flexible manufacturing system are to increase product diversity, enhance the quality of products and services, increase the speed of production, and improve customer satisfaction.

Flexible manufacturing systems (FMS) encompass any manufacturing process that can be customized to meet specific customer requirements. These systems allow manufacturers to reduce the time needed to produce a product and increase the number of products they can manufacture in a given period of time.

Mass Production or Flow production

- One of the best examples of mass production is the manufacturing process adopted by Ford.

- Mass production is also known as flow production or assembly line production.

- It is one of the most common types of products used in the automobile industry and is also used in industries where continuous production is required.

- An Assembly line or a mass production plant typically focuses on specialization.

- There are the multiple workstations installed and the assembly line goes through all the workstations turn by the turn.

- The work is done in a specialized manner and each workstation is responsible for one single type of work.

- As a result, these workstations are very efficient, and the production due to which whole the assembly line becomes productive and efficient.

- The Products which are manufactured using mass production are very standardized the products.

- High sophistication is the used in manufacturing of the products.

- If the 1000 products are manufactured using mass production, each one of them should to be the exactly same.

- There should be no deviation in the product manufactured.

Part selection problems in flexible manufacturing system

The integrated part type selection problem and machine loading problem are considered NP-hhard problems in the production planning of flexible manufacturing systems (FMS) and strongly determine the system’s efficiency and productivity. The integrated problems are modelled and solved simultaneously by using Variable neighbourhood Search (VNS). A new neighbourhood structure is designed to enable the VNS to produce near-optimum solutions in a reasonable amount of time.

The proposed Variable neighbourhood Search (VNS) improves the flexible manufacturing system’s (FMS) performance by considering two objectives: maximising system throughput and maintaining balance in the system. The overall stages in the flexible manufacturing system (FMS) environment are depicted in Fig. 1. Problems addressed in this paper are shown in the grey areas. The scheduling and assembly operations problems can be solved after solutions to the part type selection and machine loading problems are obtained.

Continuous production or Process production

- There is a lot of confusion between mass production and the continuous production.

- It can be the differentiated by a single element.

- The amount of mechanical work the involved.

- In the Mass production, both machines and humans work in the tandem.

- However, in the continuous production, most of the work is done by machines rather than humans.

- In the continuous production production is the continuous, 24×7 hours, all days in the year.

- A good example of the Continuous production is the brewing.

- In brewing, the production goes on 24 h

- There is a lot of the confusion between mass production and the continuous production.

- It can be the differentiated by a single element.

- The amount of mechanical work the involved.

- In the Mass production, both machines and humans work in the tandem.

- However, in the continuous production, most of the work is done by machines rather than humans.

- In the continuous production production is the continuous, 24×7 hours, all days in the year.

- A good example of the Continuous production is the brewing.

- In brewing, the production goes on 24 hours a day and the 365 days a year. This is because brewing takes a lot of time and production is the important.

- As a result, there is the continuous input of raw materials such as malt or water, and there is the continuous output in the form of beer or other alcoholic drink.

- The key factor in this is that brewing and the fermentation process itself is the time-consuming, and the maximum time is spent in the fermentation which is the continuous process

- There are many chemicals which are manufactured in the form of a continuous process due to the huge demand across the world. Similarly Plastic industry is the known to adopt the continuous production methodology where production can go continuously for the weeks or months depending on the demand.

- Once the production starts you only need to feed in the raw material, and the machines turn out the finalized products.

- ours a day and the 365 days a year. This is because brewing takes a lot of time and production is the important.

- As a result, there is the continuous input of raw materials such as malt or water, and there is the continuous output in the form of beer or other alcoholic drink.

- The key factor in this is that brewing and the fermentation process itself is the time-consuming, and the maximum time is spent in the fermentation which is the continuous process

- There are many chemicals which are manufactured in the form of a continuous process due to the huge demand across the world. Similarly Plastic industry is the known to adopt the continuous production methodology where production can go continuously for the weeks or months depending on the demand.

- Once the production starts you only need to feed in the raw material, and the machines turn out the finalized products.

FMS Data Base Systems

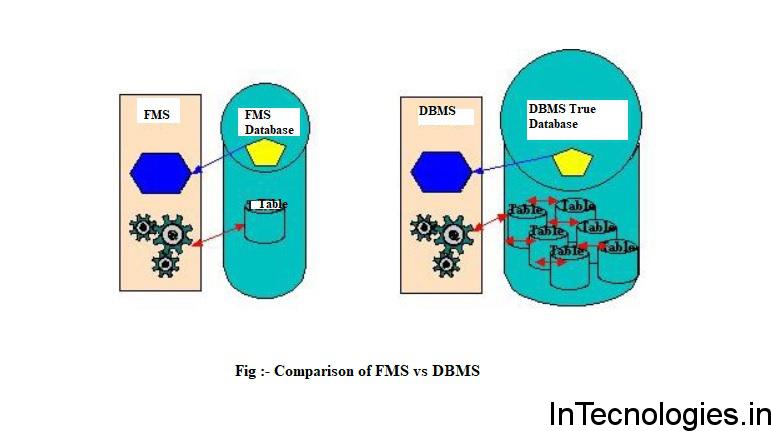

The Database Management System (DMS) is a combination of computer software, hardware, and information designed to electronically manipulate data via computer processing. Two types of database management systems are the Database Management System (DBMS) and the File Management System (FMS). In simple terms, a File Management System (FMS) is the Database Management System that allows access to single files or tables at a time. The File Management System (FMS) accommodates flat files that have no relation to the other files. The File Management System (FMS) was the predecessor of the Database Management System (DBMS), which allowed access to multiple files or tables at a time (see Figure below).

The different types of flexibility

1. Machine Flexibility

It is the capability to adapt a given machine in the system to a wide range of production operations and t part styles. The greater the range of operations, and part styles greater will be the machine flexibility. The various factors on which machine flexibility depends are the Setup or changeover time Ease with which the part-programs can be downloaded to the machines Tool storage capacity of machines Skill and the versatility of workers in the systems.

2. Production Flexibility

It is the range of the part styles that can be produced on the systems. The range of part styles that can be produced by the manufacturing system at moderate cost and the time is determined by the process envelope. It depends on the following factors: Machine flexibility of the individual stations Range of machine flexibilities of all stations in the system.

3. Mix Flexibility

It is defined as the ability to change the product mix while maintaining the same total production quantity, that is, producing the same parts in different proportions. It is also known as process flexibility. Mix flexibility provides protection against market variability by accommodating changes in the product mix due to the use of shared resources. However, high mix variations may result in the requirement for a greater number of tools, fixtures, and other resources. Mixed flexibility depends on factors such as: Similarity of parts in the mix Machine flexibility Relative work content times of the parts produced

4. Product Flexibility

It refers to the ability to change over to a new set of products economically and quickly in response to changing market requirements. The change over time includes time for the designing, planning, tooling, and featuring of the new products introduced in the manufacturing line-up. It depends on the following factors: Relatedness of the new part design with the existing part family Off-line part programme preparation machines provide flexibility.

5. Routing Flexibility

It can be defined as the capacity to produce parts on an alternative workstation in the case of equipment breakdowns, tool failures, and other interruptions at any particular station. It helps increase throughput in the presence of external changes such as product mix, engineering changes, or new product introductions. Following are the factors that determine routing flexibility: Similarity of parts in the mix Similarity of the workstations Common tooling.

6. Volume Flexibility

It is the ability of the system to vary the production volumes of different products to accommodate changes in demand while remaining profitable. It can also be termed as capacity flexibility. Factors affecting the volume flexibility are: Level of manual labour performing production Amount invested in capital equipment.

7. Expansion Flexibility

It is defined as the ease with which a system can be expanded to foster total production volume. Expansion flexibility depends on the following factors: Costs incurred in adding new workstations and training workers Easiness in the expansion of the layout Type of part handling system used.

Types of Fms Layouts

The different types of FMS layouts are

- Progressive or Line Type

- Loop Type

- Ladder Type

- Open field type

- Robot cantered type

1. Progressive or Line type

The machines and handling system are arranged in the line as shown in the Fig.1.4 (a). It is the most appropriate for the system in which part progress from the one workstation to next in the well-defined sequence with the back flow. The operation of this type of system is the very similar to transfer type. Work always flows in the unidirectional path as shown .

2. Loop Type

The basic loop configuration is as shown in Fig. 1.4 (b). The parts usually move in one direction around the loop, with the capability to stop and be transferred to any station. The loading and unloading stations are typically located at one end of the loop.

3. Ladder Type

The configuration is as shown in Fig. 1.4 (c). The loading and unloading stations are typically located at the same end. The sequence for the operation or transfer of parts from one machine tool to another is in the form of ladder steps, as shown.

4. Open Field Type

The configuration of the open field is as shown in Fig. 1.4 (d). The loading and unloading stations are typically located at the same end. The parts will go through all the substations, such as the CNC machines, coordinate measuring machines, and wash station, with the help of the AGVs from one substation to another.

5. Robot Cantered Type

A robot-centred cell is a relatively new form of flexible system in which one or more robots are used as material handling systems, as shown in Fig. 1.4 (e). Industrial robots can be equipped with grippers that make them well suited for handling rotational parts.

Objectives of an FMS

A study, carried out with West Germany manufacturing has shown the major aims of installing an FMS to be

- Decreased Lead Times

- Increased Throughput

- Increased machine utilization

- Improved Due Date Reliability

- Decreased Store Inventors Levels

- decreased Work in Progress

- Increased Quality

Definition

A flexible manufacturing system (FMS) is arrangement of machines interconnected by the transport system. The transporter carries work to the machines on pallets or other interface units so that work-machine registration is accurate rapid and automatic. A central computer controls both machines and the transport system.

Basic Components of FMS

The basic components of FMS are

- Workstations

- Automated Material Handling and Storage system.

- Computer Control System

1. Workstations

In present-day applications, these workstations are typically computer numerical control (CNC) machine tools that perform machining operations on families of parts. Flexible manufacturing systems are being designed with other types of equipment, including inspection stations, assembly works, and sheet metal presses. The various workstations are

- Machining canter’s

- Load and unload stations

- Assembly work stations

- Inspection stations

- Forging station

- Sheet metal processing, etc.

2. Automated Material Handling and the Storage system

The various automated material handling systems are used to transport work parts and subassembly parts between the processing stations, sometimes incorporating storage into the function. The various functions of automated material handling and the storage system are

- Random and the independent movement of work parts between workstations

- Handling of a variety of the work part configurations

- Temporary the storage

- Convenient access for the loading and unloading of the work parts

- Compatible with the computer control

3. Computer Control System

It is the used to coordinate activities of the processing stations and the material handling system in the flexible manufacturing system (FMS). The various functions of the computer control system are

- Control of each work station

- Distribution of control instruction to the work station

- Production control

- Traffic control

- Shuttle control

- Work handling system and the monitoring

- System performance monitoring and the reporting

The flexible manufacturing system (FMS) is the most suited for the mid-variety, mid-value production range.

0 Comments